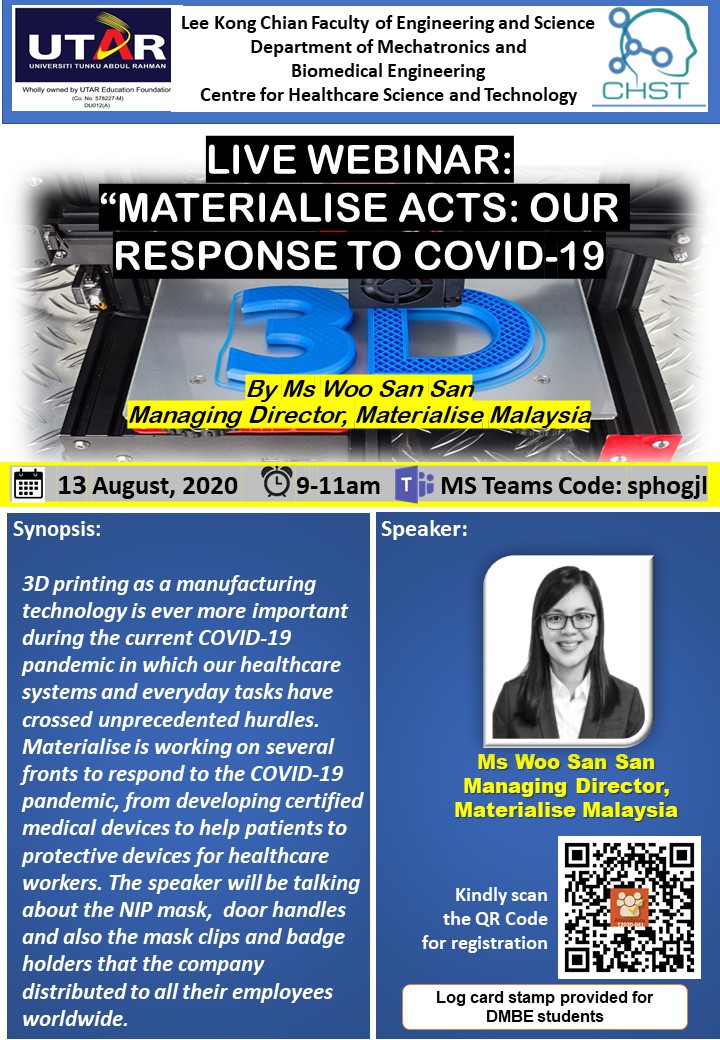

Date: 6-Aug-2020

The speaker started the session by explaining the nature of business and the global standing of Materialise as a multi-national company that applies 3D-printing, engineering and software development. The speaker also explain the concept of additive manufacturing also known as 3D-printing to the students and disclosed how various companies worked together to 3D-print much sought-after medical tools such as face shield, nasopharyngeal swaps, clips and clasps for face mask, respirator adapters and etc. One of the biomedical engineer graduated from UTAR has helped to print and distributed face shield to a few hospital in local region during the MCO period. Among the issues highlighted by the speaker were how Materialise listened and adopted suggestions from its employees to come out with various innovative products that proved to be very useful and highly effective in infection control and prevention practices. The speaker also talked about the NIP mask, door handles and also the mask clips and badge holders that the company distributed to all their employees worldwide.